The Story Behind Repmold

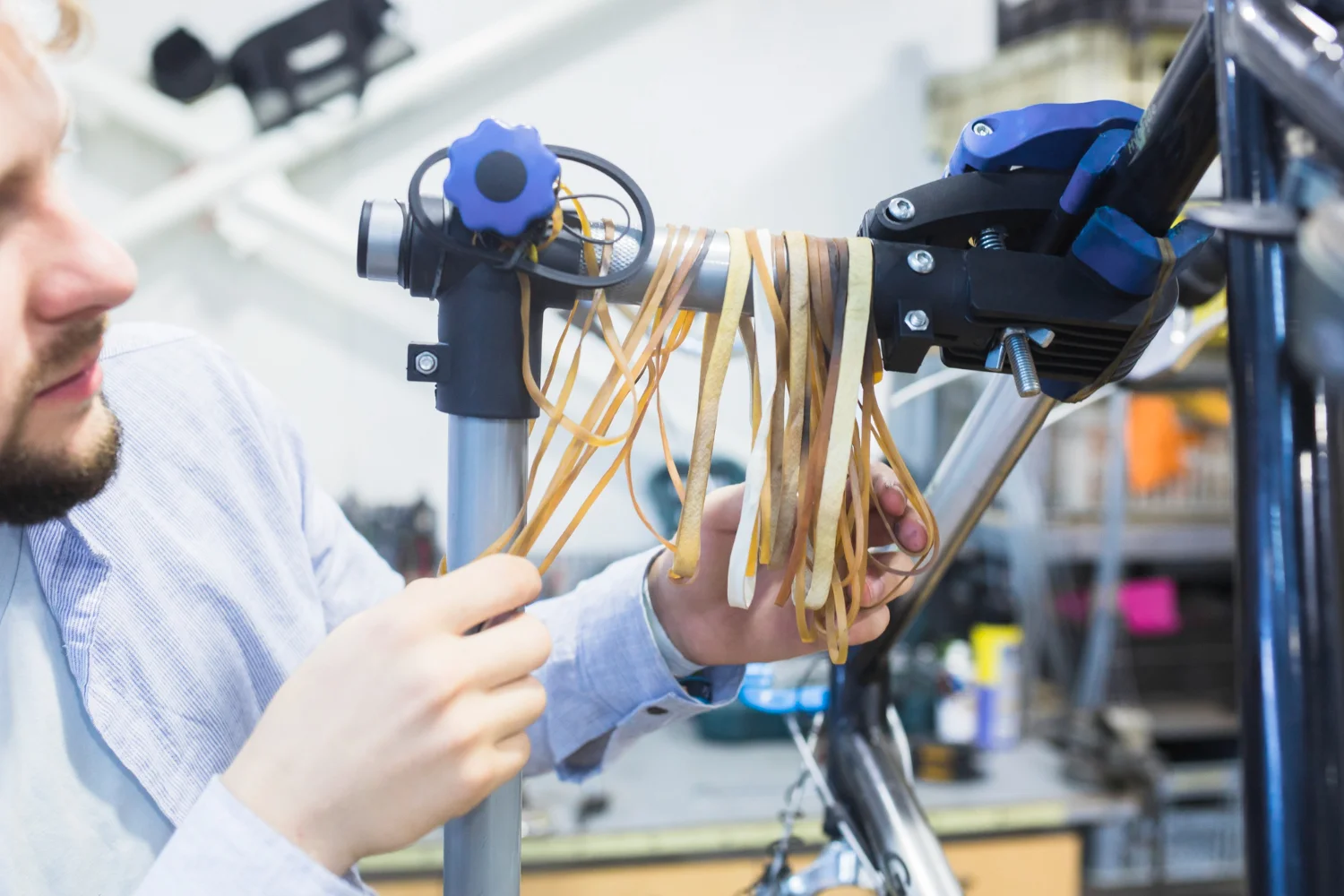

It all began on a rainy afternoon when a small team of engineers was struggling to find a reliable solution for precision molding in manufacturing. Every existing tool seemed either too expensive or too fragile. After hours of experimentation and countless prototypes, they finally developed a solution that worked seamlessly. This innovation was called Repmold. Unlike anything they had tried before, Repmold offered durability, accuracy, and efficiency that transformed the way products were made. From that moment, Repmold became more than just a tool it became a trusted partner for manufacturers worldwide.

What is Repmold?

Repmold is an advanced molding solution designed for precision manufacturing. It is specifically tailored to create high-quality molds with minimal errors, helping manufacturers save time and reduce waste. Repmold is known for its strong material composition, ease of use, and adaptability across various industries.

Key features of Repmold include:

- Durable Material: Repmold is built to withstand heavy usage without breaking or deforming.

- High Precision: It ensures molds are accurate, reducing the chances of product defects.

- User-Friendly Design: Repmol is easy to use, even for first-time operators, with simple setup and handling.

Why Repmold Stands Out

In a market full of molding solutions, Repmold sets itself apart with its unique combination of performance, affordability, and versatility.

Superior Performance

Repmold delivers consistent, high-quality results in every application. Its advanced design reduces errors, increases production speed, and ensures uniformity across all molds.

Cost-Effective Solution

Unlike traditional molding systems that require expensive maintenance, Repmol provides exceptional quality at an affordable price. Businesses can save significantly without compromising output quality.

User-Friendly Design

The intuitive design of Repmol makes it accessible for both beginners and experienced technicians. Its simple operation reduces training time and minimizes human error.

Applications of Repmold

Versatile Uses in Manufacturing

Repmold is highly versatile and can be used across multiple manufacturing applications, including:

- Automotive Industry: Producing precise components for engines and interiors.

- Consumer Goods: Creating molds for household items and electronics.

- Medical Devices: Manufacturing high-precision parts used in healthcare equipment.

Real-Life Examples

Several companies have successfully integrated Repmold into their workflows. For instance, a small electronics manufacturer saw a 30% increase in production efficiency after adopting Repmol. Similarly, a medical equipment supplier reported fewer defective parts and higher overall product quality.

Tips for Maximizing Repmold Benefits

- Regular Maintenance: Clean and inspect the Repmold after each use to maintain performance.

- Follow Manufacturer Guidelines: Always use recommended temperatures and materials for optimal results.

- Training: Provide staff with proper training to fully utilize Repmold’s capabilities.

Conclusion

From a small team’s innovation to becoming a trusted solution for manufacturers worldwide, Repmol has proven its value across industries. Its durability, precision, and ease of use make it an ideal choice for businesses seeking efficiency and quality. By adopting Repmold, manufacturers are not only improving their production process but also embracing a future of innovation and reliability.